We have summarized in points the most important assembly tips during construction.

We drew on twenty European technical catalogs,

which are enriched by our own experiences along with

technical drawings.

We have summarized in points the most important assembly tips during construction. We drew on twenty European technical catalogs, which are enriched by our own experience together with technical drawings.

1. We recommend entrusting the processing of project documentation and assembly to an experienced construction company with the necessary technology.

2. Everything to check the entire construction, safety of workers, project documentation, construction plans, verticality, horizontality, preparation of tools and techniques and sandwich panels.

3. It is best to perform the installation when it is not raining, snowing, or blowing, when there is no dense fog and in the evening only with good lighting.

4. Assembly work, taking into account the specifics of a specific project, is carried out at temperatures from -10 °C to +40 °C.

5. For wall panels, at least a foundation bar, sealing tape and sheeting elements are installed at the plinth (see technical drawings).

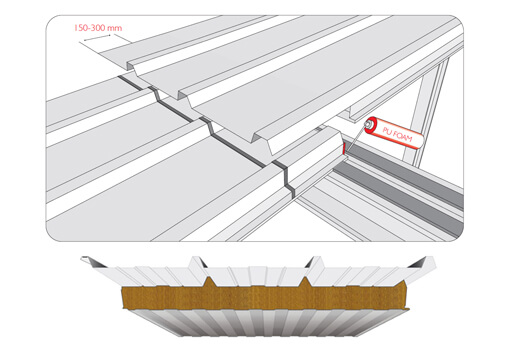

6. TEX galvanized self-tapping screws with EPDM washers are used to fasten wall and roof panels to steel, wood or concrete. Stainless steel screws are used in a more aggressive environment. When fixing the TEX self-tapping screws, make sure that the rubber EPDM pad only slightly expands.

7. Calots are an important part of high-quality fixing of roof panels.

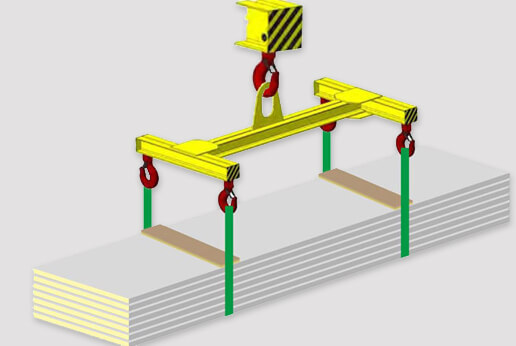

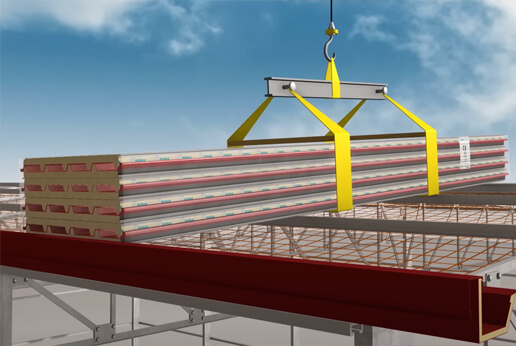

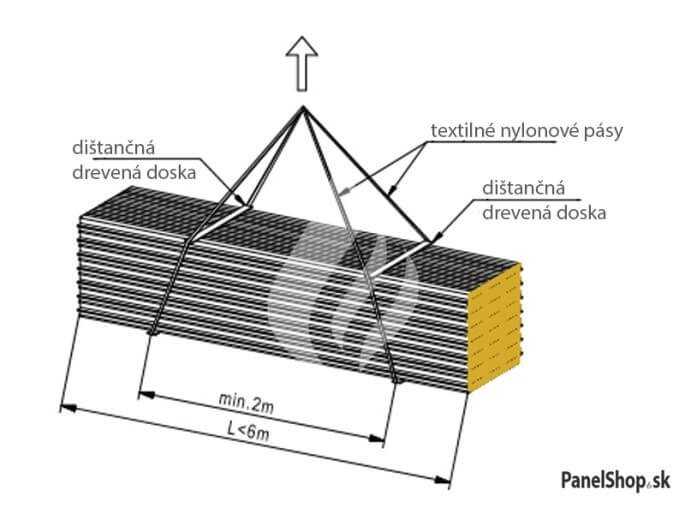

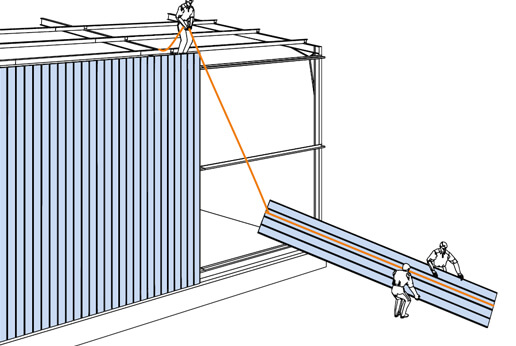

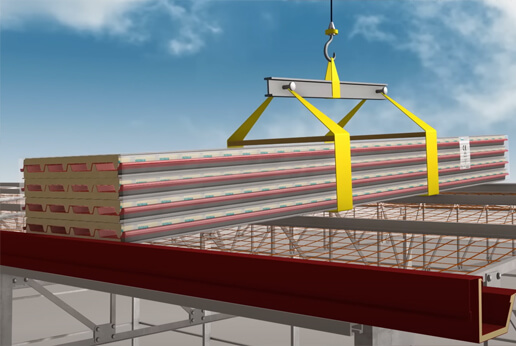

8. The panels can be moved either by means of a vacuum lifter (recommended), by means of a mechanical gripping device (lifting clamps) and a crane, but also manually by means of clamping belts.

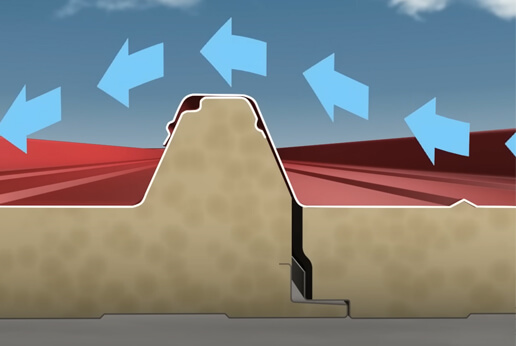

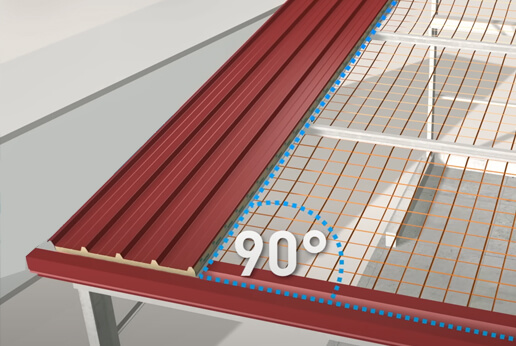

9. The installation direction should be opposite to the prevailing wind direction for both roof and wall panels.

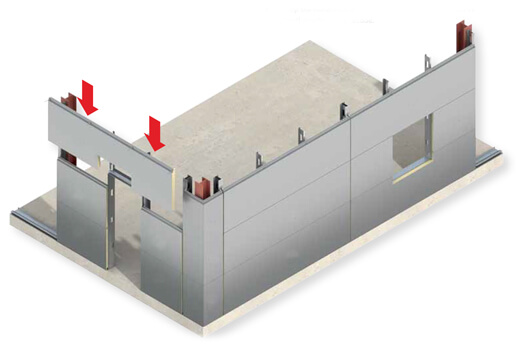

10. In the case of roof panels, there may be a situation when there are more rows and the panels are connected by a longitudinal overlap, which is created by undercutting from 150 to 300 mm, depending on the slope of the roof. (you can request undercutting when ordering)

11. Before fixing, put down the protective transparent film. The foil must be removed within 3 months, because the paint and the top of the sheet will be damaged.

12. We recommend sticking sealing tapes over the entire structure and at the sheeting elements.

13. The horizontal and vertical attachment of the wall panels must be perpendicular to the structure and aligned according to the spirit level. We align the roof panels at 90° also to the structure.

14. In the case of roof panels, it is recommended to use a crane to move the entire package to the roof of the building with subsequent fixing. Of course, this also applies to wall-mounted ones, so that the package is as close as possible to the installation.

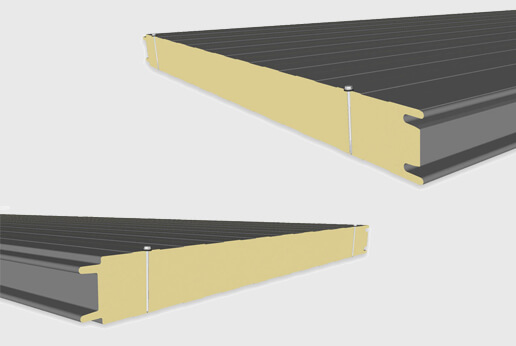

15. The panels fit together easily because they use a tongue-and-groove system on both types of panels.

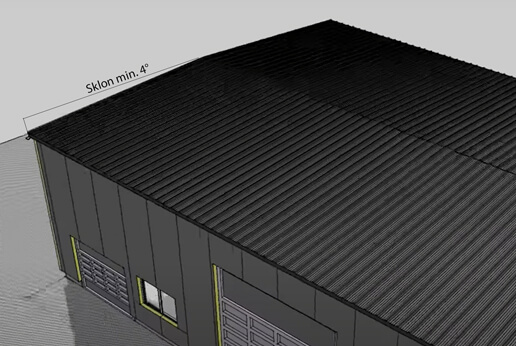

16. The minimum slope for roof panels is 4%, and when they are connected in several rows, 7%.

17. In general, it is easier to cut holes in the panels before installation, but they can also be cut afterwards.

18. Circular saws or straight line saws are used for cutting panels and not carbon grinders (flexes), which will damage the surface of the panel. We recommend placing the panels on stands (goats) before cutting.

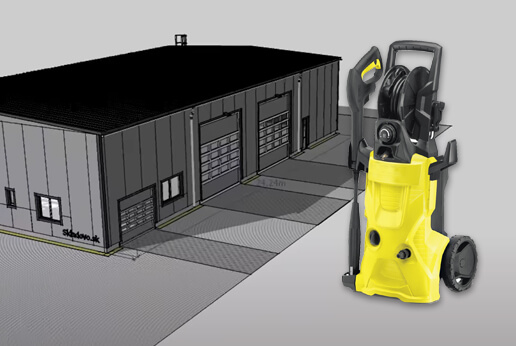

19. We recommend an inspection of the facade, roof panels, cladding elements and gutter system once a year. After the inspection, any damage must be removed and all panels washed with a low-pressure device with a non-aggressive cleaning agent and a sponge.

20. According to the plans and procedure, we install important functional, protective and aesthetic cladding elements together with sealing tapes.

21. The sandwich panel system can be mounted on all types of structures such as wood, concrete or steel. A steel frame is most often used.

22. Horizontal laying of panels is recommended for several reasons, namely: better mechanical and load conditions, cheaper construction, lighter construction, no intermediate beams, simple installation, easier transport and handling due to the shorter length of the panels.

23. Structural profiles, such as thin-walled cages, are intended for use primarily as cages for ceilings, roofs and walls of steel halls. Thin-walled profiles are available as standardized Z and C profiles or as special profiles. They enable precise and quick assembly. These profiles are used as prisons and wings for all types of halls.

24. During construction, you will need a cordless screwdriver, a circular saw, a jigsaw, a spirit level, a protractor, pur foam, sealant, a leveling device, sealing tapes, a tape measure, clamping bands, calottes, tinkering tools, screws, a marker, a rubber hammer, goats ( racks), and other tools according to the specific needs of the building.

25. Surveys show that falls from a height are the most common cause of injuries in industry and construction, so pay attention to safety and professional competence when completing the work.

26. Of course, the construction also includes sheeting elements, gutter system, snow barriers, ventilation elements, roof ladders, lightning rods, filter systems, utility networks, skylights, gates, doors, windows, shelters, interior installations, exterior landscaping and more according requirements of the work.

Technical drawings and assembly visualizations

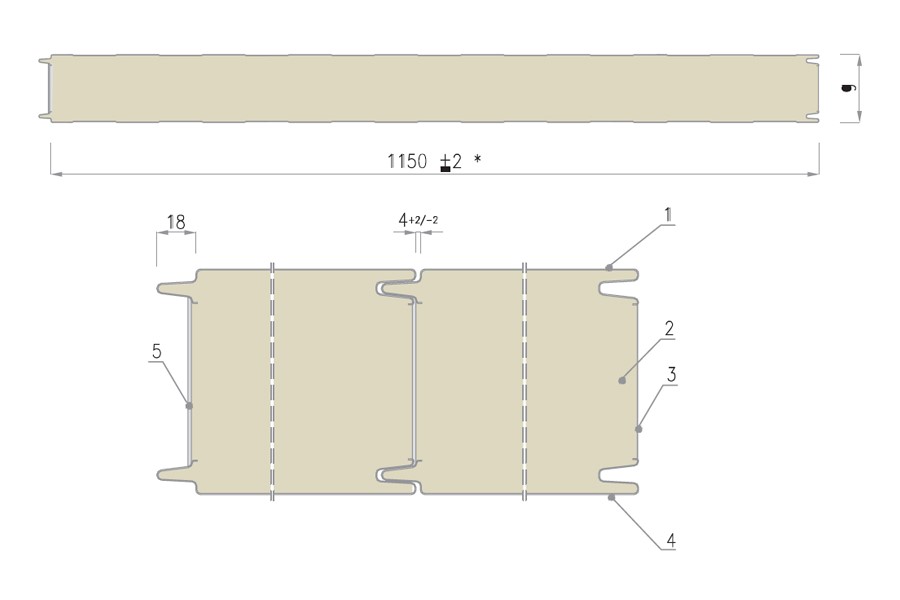

Wall sandwich panel with visible joint

Polyurethane / polyisocyanurate foam core

1. Steel sheet, external, standard thickness 0.50 – 0.60 mm

2. Polyurethane / polyisocyanurate foam core.

3. Protective strip preventing water diffusion and infiltration.

4. Steel sheet, internal, standard thickness 0.40 – 0.50 mm.

5. Factory-applied soft seal on the side edge from the side of the male lock.

*we offer different modular panel widths

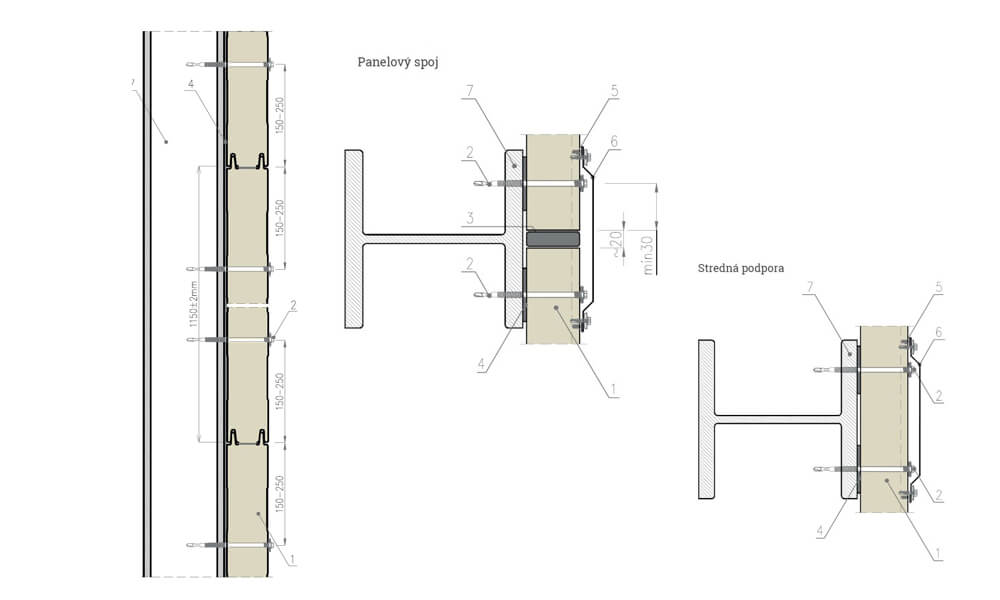

Wall panel with visible joint – fastening to the structure

Horizontal layout (for PUR, PIR, MV, EPS)

1. Wall panel with visible joint

2. Self-tapping screw with EPDM washer

3. Polyurethane foam as a filling of movement joint ~20 mm

4. Self-adhesive PES sealing tape

5. Putty, permanently plastic

6. Plating element

7. Steel profile, according to the design of the structure

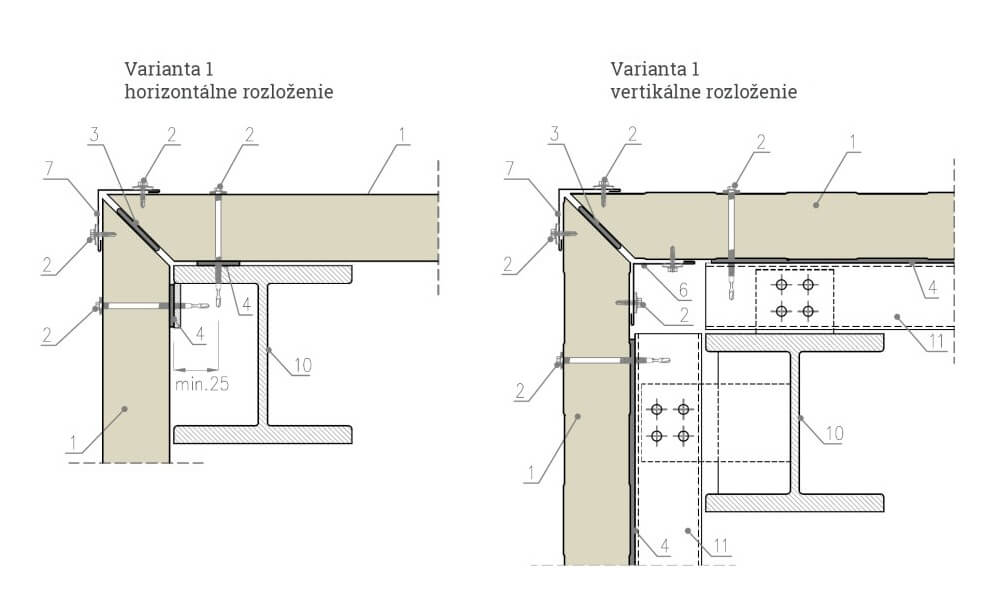

Corner joint – fastening to the structure

Wall with visible and hidden connection

1. Wall panel with visible and hidden joint (PIR, MW, EPS)

2. Self-tapping screw with EPDM washer (optionally two fasteners next to each other)

3. Polyurethane foam

4. Self-adhesive PES sealing tape

5th, 6th, 7th, 8th. flashing element

9. The cladding is locally cut for better thermal requirements

10. Steel column according to the design of the structure

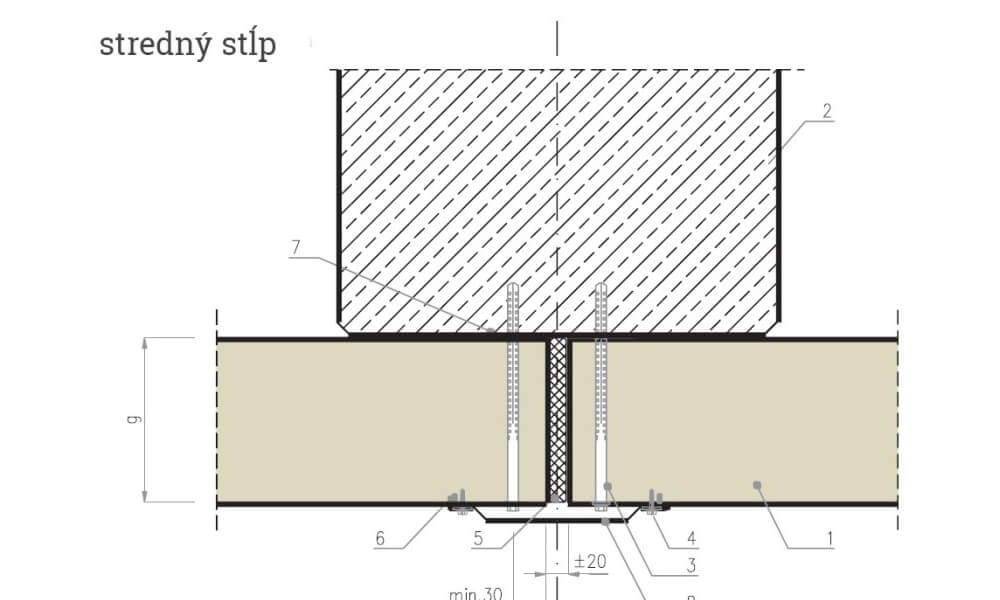

Fastening the panels to the reinforced concrete column

Wall panel, horizontal fixing

1. Wall panel, horizontal fixing

2. Reinforced concrete column

3. Screw with washer for fixing in reinforced concrete

4. Self-tapping screw with EPDM washer

5. Polyurethane foam as joint filler

6. Putty, permanently plastic

7. Self-adhesive sealing tape PES

8.,9. Flashing element

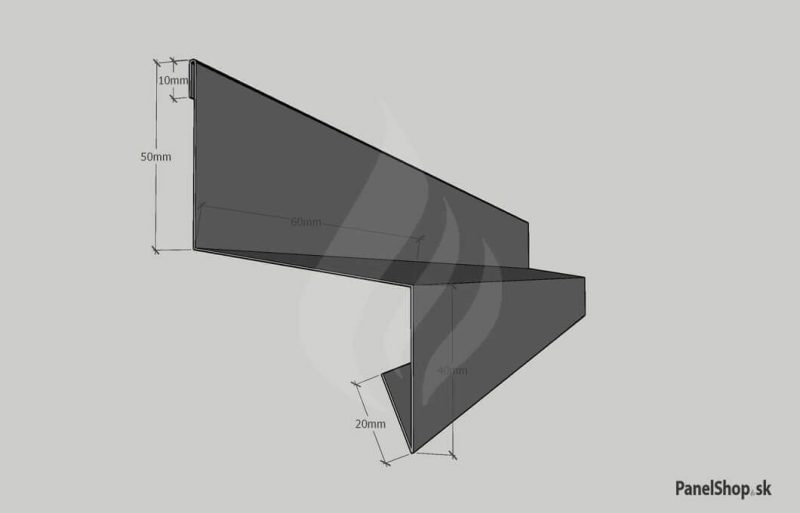

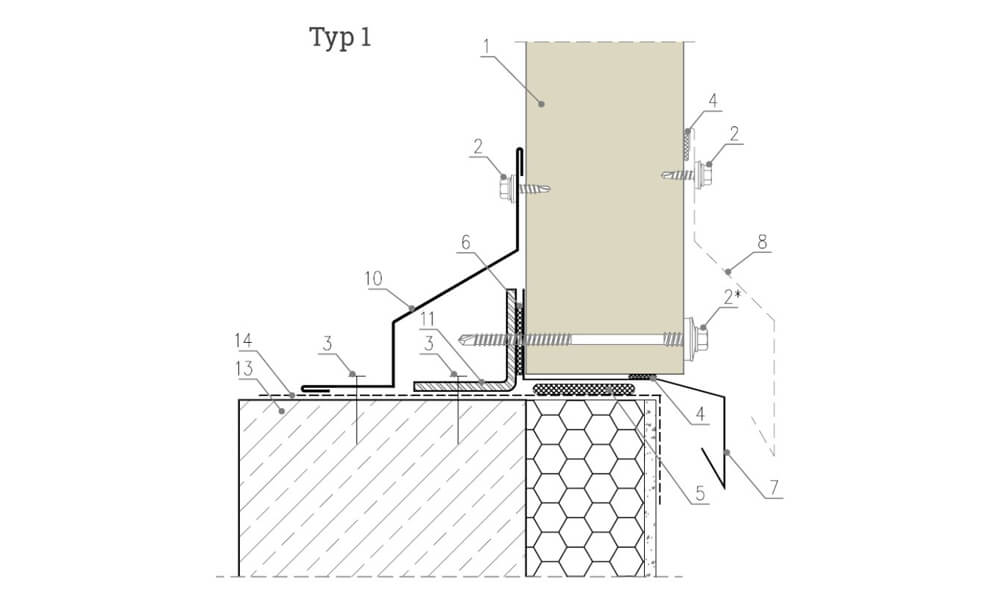

Fastening to the lower beam

Vertical fastening

1. Wall panel

2. Self-tapping screw with EPDM washer

3. Mortaring dowel

4. Putty, permanently plastic

5. Polyurethane foam

6. PES polyethylene tape

7th, 8th, 9th, 10th. flashing element

11. Steel profile L-profile, acc

construction design

12. Steel profile – wall beam

13. Ground beam

14. Waterproof seal

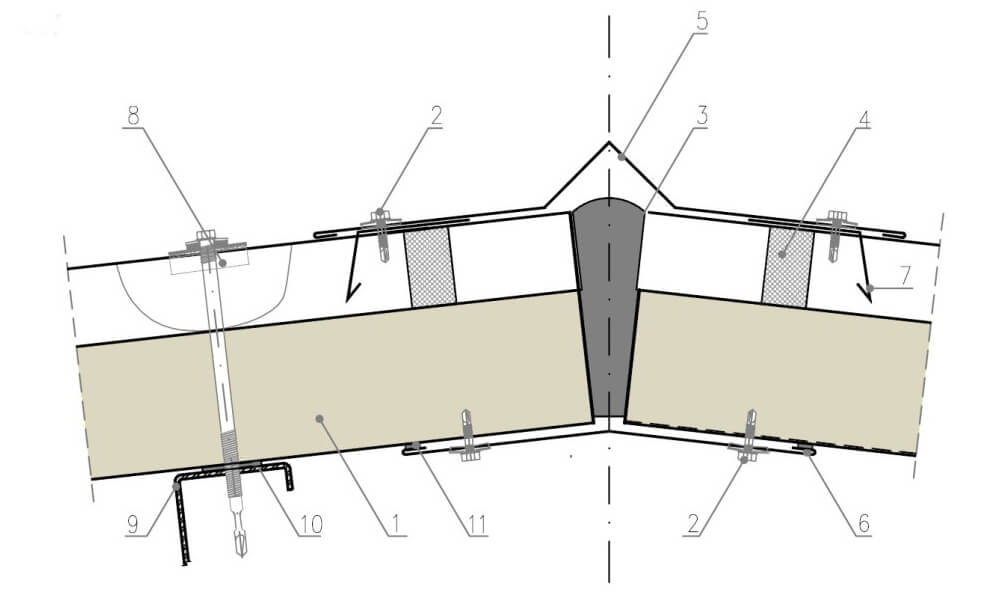

The ridge of the roof

Roof panel

1. Roof panel

2. Self-tapping screw with EPDM washer

3. Polyurethane foam

4. Polyethylene sealing strip

5th, 6th, 7th. Flashing element

8. L-03 fastener “saddle pad”

9. Prisons

10. PES polyethylene tape

11. Permanent plastic sealant

The entire technical catalog for download

Technical data, examples, visualizations, manuals.

We have drawn from twenty European technical catalogs, which are enriched with our own experience. Here you will find all the technical information about panels and accessories.

Contents of the technical catalog:

- What to do when the panels arrive ? (p. 3 – 6) Packaging, transportation, unloading, storage.

- Main technical information about panels (p. 7 – 71) In general about the product, the most important advantages, basic types, thicknesses and joints, main technical data, colors, plating, surface treatments, types of profiles offered, fire resistance, load-bearing capacity of panels, acoustic properties, certificates.

- How are sandwich panels mounted? (p. 72 – 112) We have summarized the most important installation tips during construction in points. We have drawn from twenty European technical catalogs, which are enriched with our own experience. You can find high quality technical drawings in the second section.

- Plate elements and their location (p. 113 – 149) Visualization of the cladding element + placement examples. We offer two types of plating elements, 41 pcs and 33 pcs. Option to enter your own parameters..

- Structural profiles of thin-walled purlins (p. 150– 152) Thin-walled purlins are intended for use primarily as purlins for ceilings, roofs and walls of steel halls.

- Self-tapping screws, Saddle Washers (Calots), Sealing tapes (p. 153 – 159)

Technical data, examples, visualizations, manuals. We have drawn from twenty European technical catalogs, which are enriched with our own experience. Here you will find all the technical information about panels and accessories.