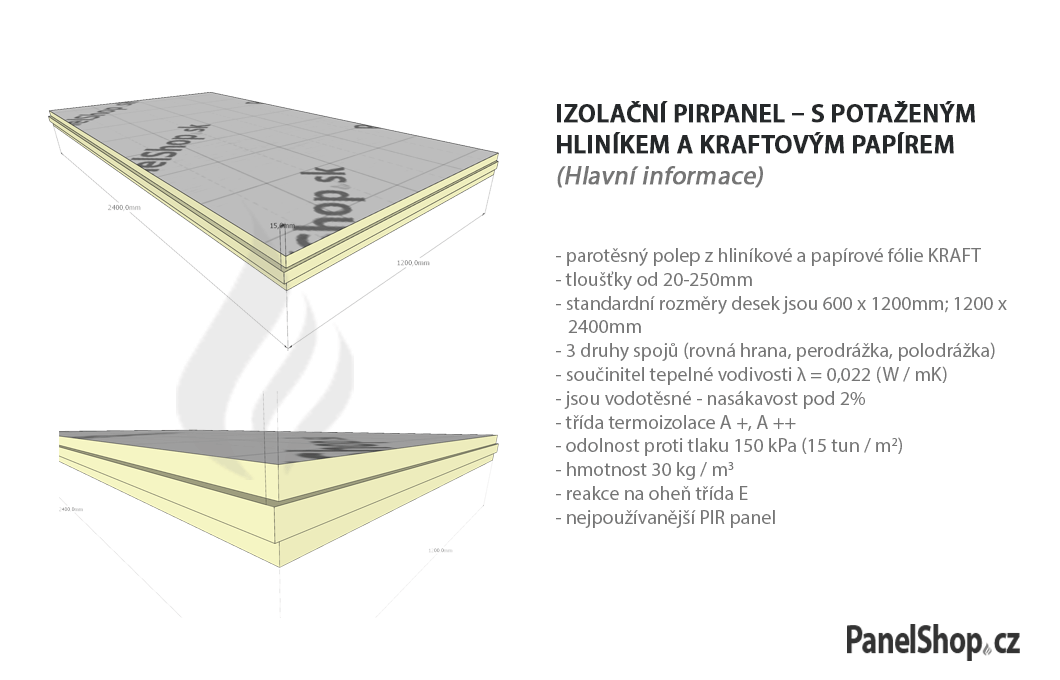

PIR insulation panels are thermal insulation boards with a core of modified polyurethane (polyisocyanurate – PIR), which are protected on both sides by a surface treatment with different types of adhesive and three types of joints. Thicknesses are from 20-250mm. The standard dimensions of the boards are 600 x 1200 mm; 1200 x 2400mm. Dimensions with plasterboard 1200 x 2600 (mm).

They are used to insulate roofs, perimeter walls, terraces, ceilings and floors of houses, industrial buildings, agricultural buildings, block of flats, storage areas, shops, manufacturing plants, sports halls, freezer and cold storage areas.

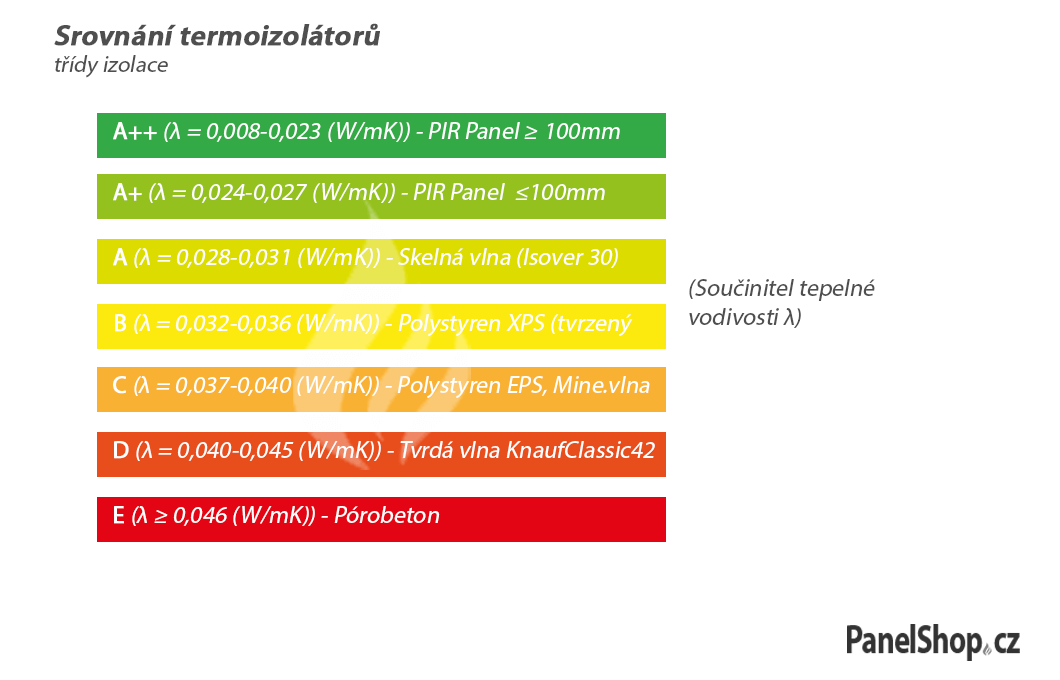

It’s basically a 21st century hit. The coefficient of thermal conductivity (λ = 0.023 W / mK) has the best of all available insulation materials on the market. Much better than mineral wool and polystyrene.

More technical data

- thicknesses are from 20-250mm (all types)

- standard board dimensions are 600 x 1200mm; 1200 x 2400mm, with plasterboard 1200 x 2600mm

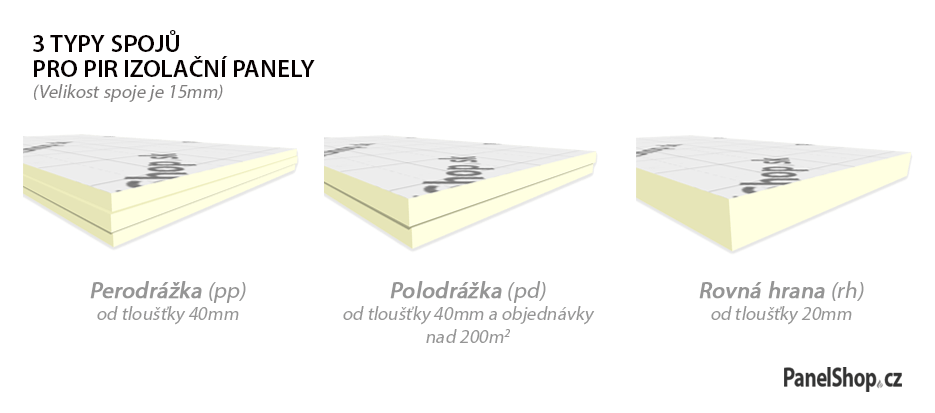

- 3 types of joints to choose from (straight edge, tongue groove (from 40mm), half groove (from 30mm over 2000m2)) (15mm is the size of the joint)

- super insulating properties (thermal conductivity coefficient λ = 0.024-0.026 (W / mK), much better than mineral wool or polystyrene)

- very low water absorption (they are basically waterproof – absorbency below 2%)

- thermal insulation class A +, A ++ (the best on the market)

- high pressure resistance of 150 kPa (15 tons / m2)

- reaction to fire classes E and F and D-s2, d0

- weight 30 kg / m3 (they are very light)

- resistance to organic compounds, ammonia, insects and rodents

- safe for the environment (both during production and during use)

- long life (it will serve for many generations, it is comparable to the life of a building)

- low weight (important for low load on the roof or structure)

- simple assembly (you can do it yourself)

- foundation can be one-layer or two-layer

- insulate roofs, floors, walls, ceilings, basements, foundations of farm buildings, green roofs (insulate everything)

- vapour-tight and vapor-permeable (depending on the type of surface treatment)

- do not contain substances or elements harmful to human life such as skin, respiratory tract or eye irritation

- They can also be recycled and largely reused

- accessories include vapor-permeable foil, fastening screws, sealing tape

All species we offer

We offer 9 types of insulating panels. All of them have a core made of modified polyurethane (polyisocyanurate – PIR) and are protected on both sides by a surface treatment with a different type of adhesive.

Types of connections for PIR insulating panels

Comparison of insulation values with other materials

Examples of using PIR panels

Wherever you have previously insulated with polystyrene (XPS, EPS) or mineral wool, use PIR insulation panels instead.

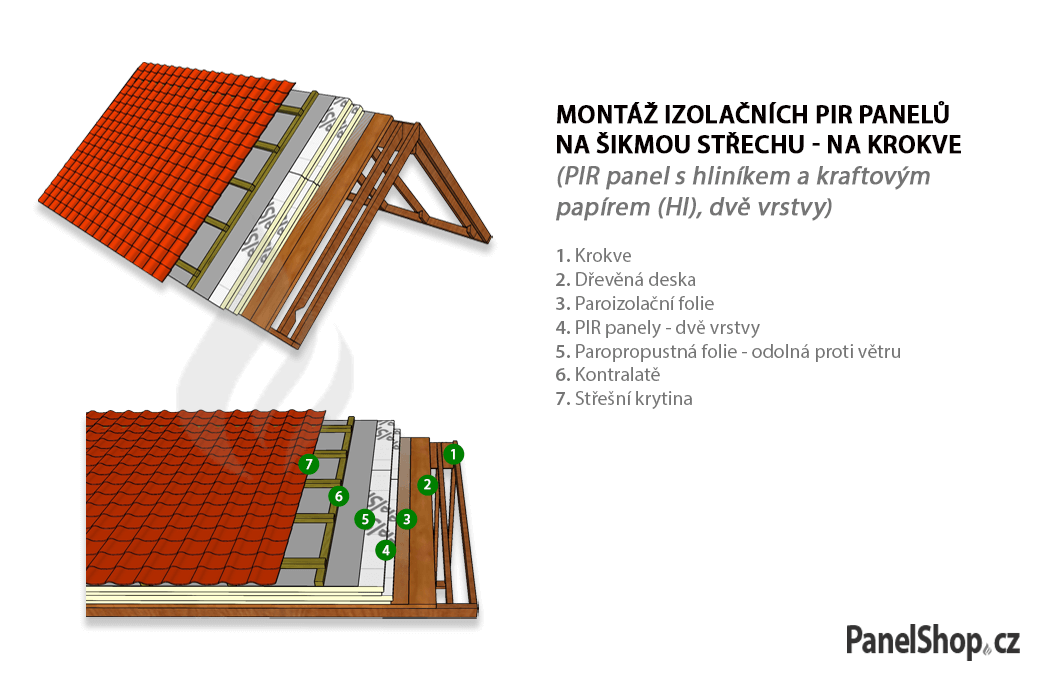

- Sloped house roofs (over-rafters, under-rafters, intermediate rafters)

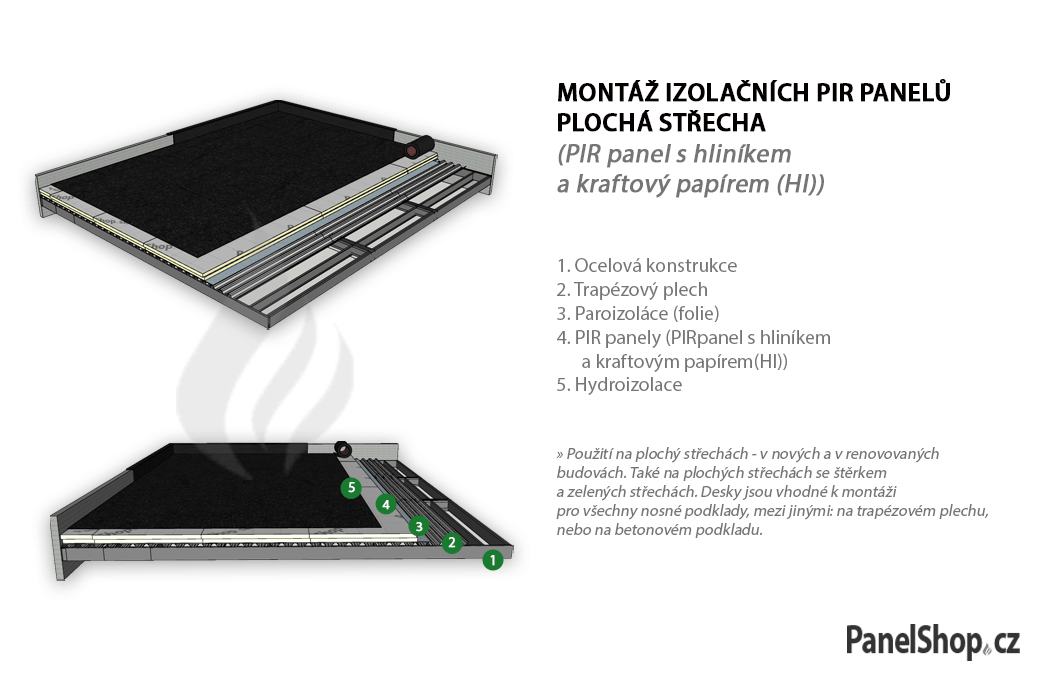

- flat roofs, green roofs, ballast roofs house

- terrace house

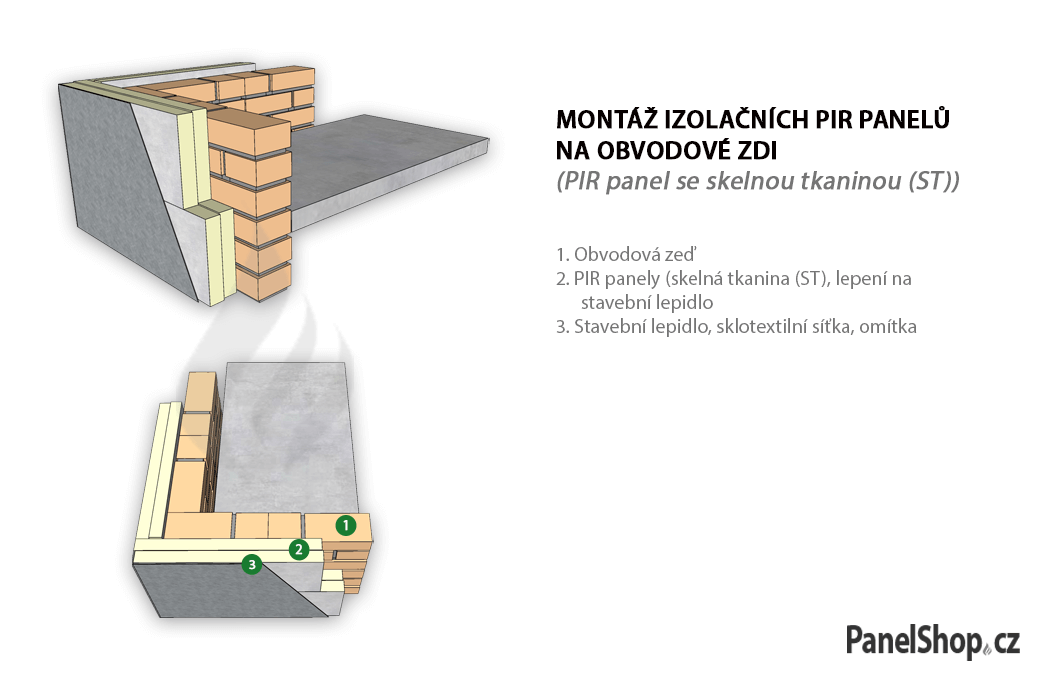

- perimeter walls of the house (internal, external)

- floors on the ground floor, ceilings between floors of the house (single-layer, two-layer)

- basement walls and house foundations

- sloped and flat roofs, green roofs, ballast roofs of industrial buildings

- floors, basements, foundations of industrial buildings

- inner and outer perimeter walls of an industrial building

- flat, gable, green, ballast roofs of apartment buildings

- internal and external perimeter walls of the apartment building

- terraces and floors of apartment buildings

(Sample of installation on a sloping roof)

(Example of installation on perimeter walls)

(Example of installation on a flat roof – industrial building, company)

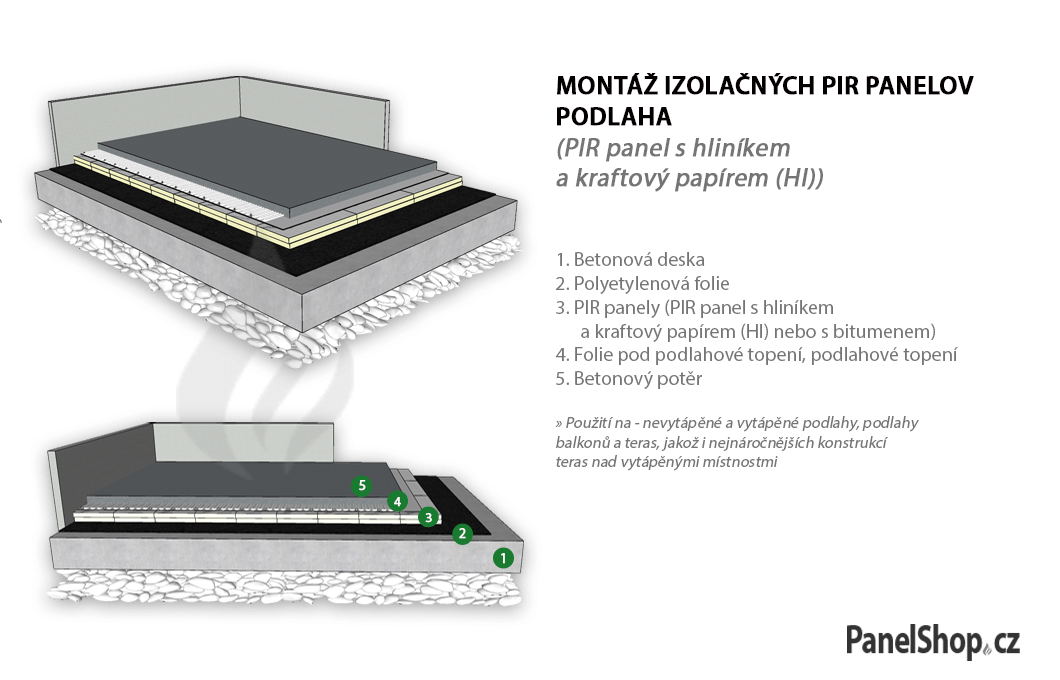

(Example of floor installation with underfloor heating)

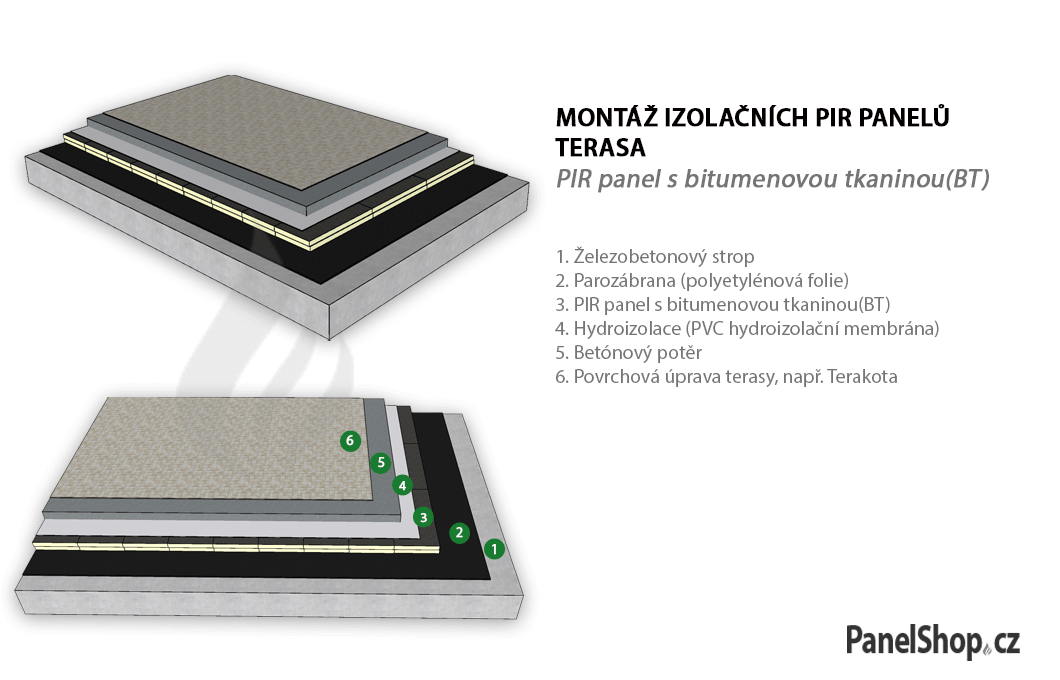

(Demonstration of assembly on the terrace)

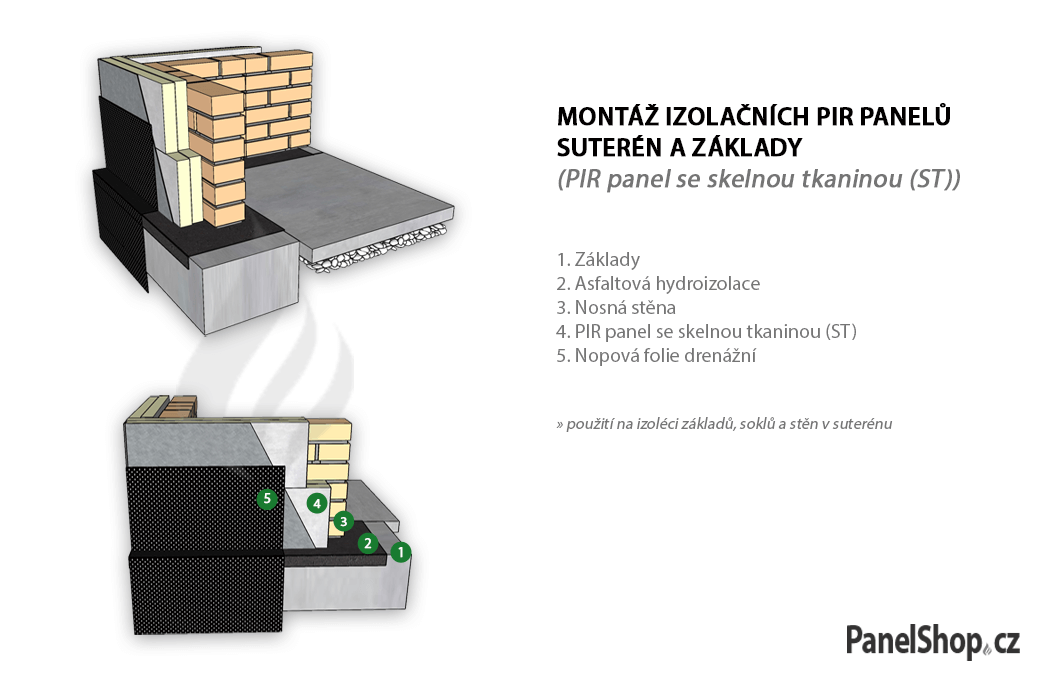

(Example of basement assembly and foundations)

Energy consumption with and without insulation (example – family.house)

Usable area: 280 m2 »wall insulation thickness: 160 mm» floor insulation thickness: 80 mm »roof insulation thickness: 200 mm» heating type: condensing gas stove.

| parameters | PIRpanel (λ = 0.023 W⁄mK) strong> | without insulation λ = 0.8 W⁄mK |

| energy consumption per year [kWh] | 23020[kWh] | 109826[kWh] |

(Really excellent numbers)

Necessary accessories

- Roof film waterproof and vapor permeable made of polypropylene

(Suitable for mounting on rafters)

- Aluminum sealing tape for PIR panel joints (50 um / 100 mm)

- Torx fixing screws for wood (lengths from 30-400mm, galvanized, head diameter Φ 6, Φ 8, 3 to 4 pieces of screws for every 1 m2, required length = panel thickness + counter battens + 40 mm to the rafter)

- Roof dowels and screws for flat roofs made of trapezoidal sheet metal (dowel lengths are 35, 55, 85, 105, 135, 155, 185, 235, 285mm – plate diameter 50mm. Screw lengths 40, 50, 60, 70, 80, 90, 100, 120, 140, 160 mm – for attaching elements to trapezoidal sheet thickness 0.5 – 0.75 mm and 0.5 – 2 x 1.25 mm). For 100 mm boards, mounted on a trapezoidal sheet, 60 mm screws and an 80 mm dowel should be used (sum of dowel lengths and screws by 40 mm > panel thickness). Consumption during single-layer installation 2 pcs per 1 m2.