The Sandwich panel is a hit of the 21st century, everything is slowly being built from it. Everywhere you look, you can see buildings made of panels, such as Tesco, Lidl, Kaufland department stores, but also industrial parks and zones, various warehouses, garages, workshops, extensions, car repair shops, shops, halls, freezer and agricultural halls. All these modern buildings are made of sandwich panels (pur / pir, mineral wool, polystyrene core), which have excellent insulating properties and a long service life of over 50 years.

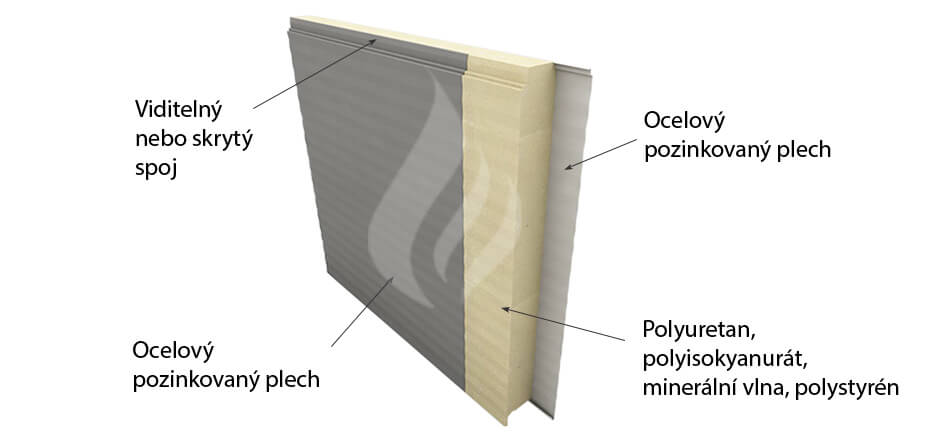

Sandwich panels are prefabricated elements that consist of two facings of galvanized sheet steel (external and internal) and an insulating core located between them. The insulating cores are either made of hardened polyurethane (PUR), polyisocyanurate foam (PIR), mineral wool or polystyrene. This core provides high-quality heat and sound insulation with high fire resistance.

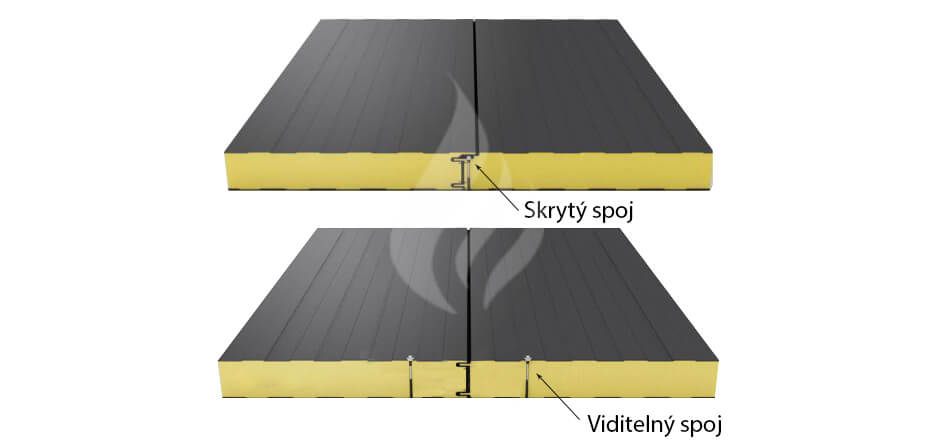

The panels are mounted vertically or horizontally on the structure. This construction can be steel, wood and reinforced concrete, or a combination of them with a hidden / visible connection and a tongue-and-groove system.

Panels are widely used in the construction of buildings, storage areas, industrial and manufacturing warehouses. In the commercial sphere, they are used for the construction of car showrooms, car repair shops, garage spaces, agricultural warehouses and halls, cold storage and freezer rooms.

The panels are designed to cover interior, exterior walls, ceiling and roof skeleton structures.

Main beneficial construction parameters:

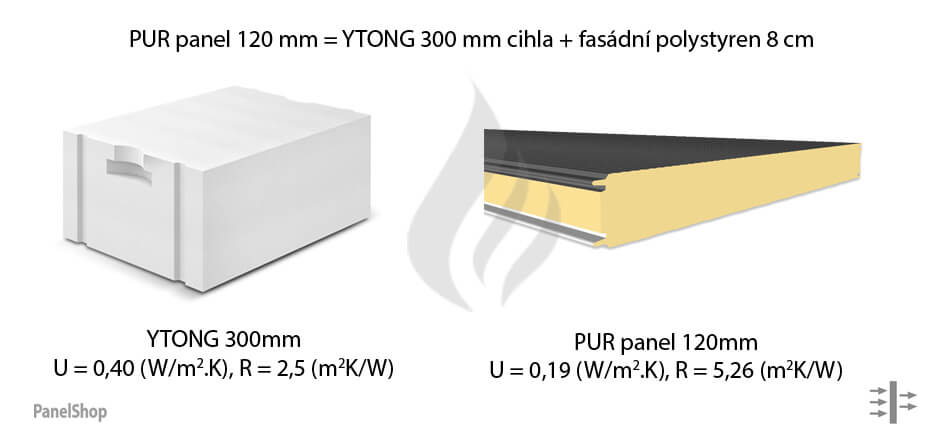

- high quality insulation properties (eg: PIR panel, 120mm has TIS U = 0.19 (W / m2.K) compared to YTONG 300mm brick plus facade polystyrene 8cm TIS U = 0.22 (W / m2. K))

- very high-quality fire properties (e.g.: fire resistance 180 mm mineral wool panel EI120 / 240, NRO)

- very high-quality acoustic insulation (e.g. 100 mm mineral panel has weighted sound insulation Rw = 31dB)

- quick assembly and minimal maintenance (faster and simpler construction than brick buildings)

- no external and internal decoration is needed

- modern aesthetic appearance, different variants of profiles and colors

- panels can be assembled vertically and horizontally

- complete environmental safety

- long service life – service life over 50 years

- vapor tightness and air tightness

Why a sandwich and not a brick…

In order to achieve thermal insulation properties like a sandwich panel, for example, we would have to insulate a standard ytong 30cm brick with 8cm polystyrene to achieve the coefficient of thermal conductivity (U) and thermal resistance (R) as with 100mm thick standard PUR panels. Coefficient of conductivity and thermal resistance are two main indicators when comparing the insulating properties of materials. The smaller the value of U the better, on the contrary R thermal resistance, the higher the better.

- PUR sandwich panel 100mm U = 0.22 (W / m2.K), R = 4.6 (m2K / W)

- PUR sandwich panel 120mm U = 0.19 (W / m2.K), R = 5.26 (m2K / W)

- YTONG 300mm brick U = 0.35 (W / m2.K), R = 2.8 (m2K / W)

- YTONG 300mm brick plus facade polystyrene 8cm U = 0.22 (W / m2.K), R = 4.6 (m2K / W)

- Solid brick 300mm U = 2.56 (W / m2.K), R = 0.39 (m2K / W)

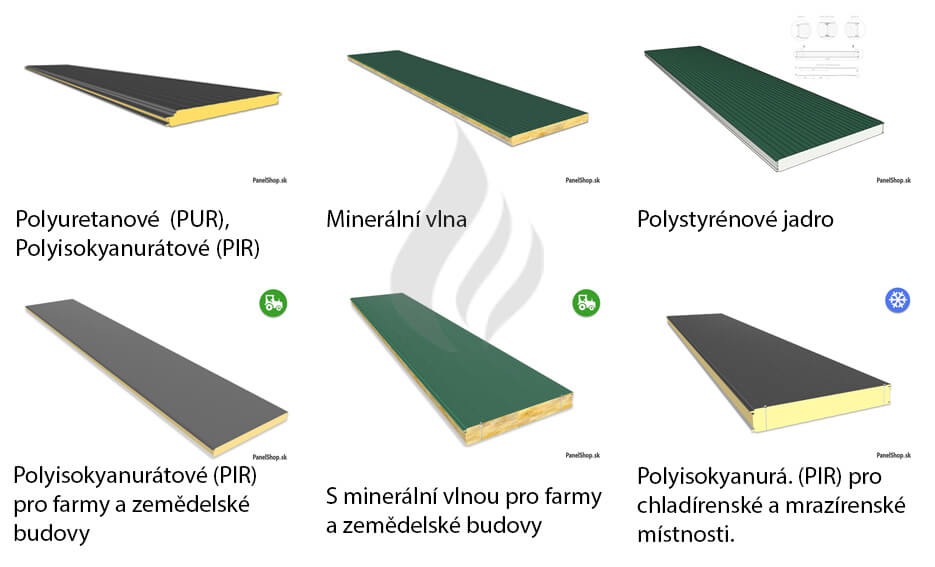

What kinds of panels are on the market…

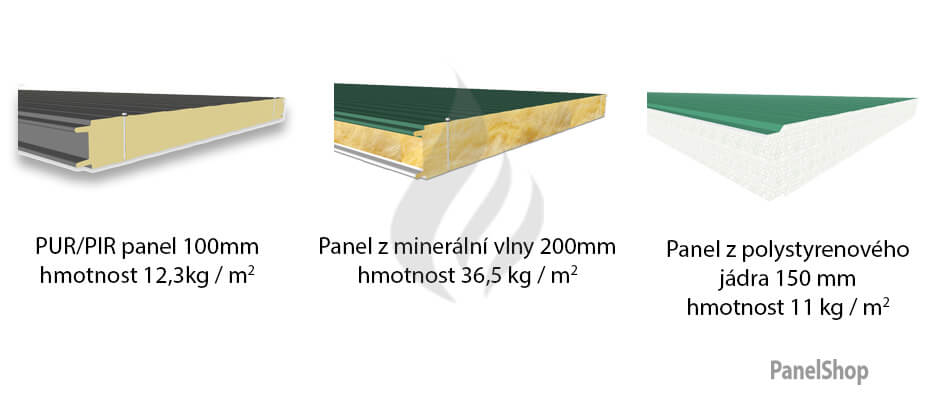

Polyurethane (PUR), polyisocyanurate (PIR), with mineral wool, polystyrene core, polyisocyanurate (PIR) for farms and agricultural buildings, with mineral wool for farms and agricultural buildings and isocyanate (PIR) for cold and freezer rooms are offered.

The types of panels are either wall (visible joint), facade (hidden joint), roof, and the joints are either visible or hidden (eg: with facades, where the head of the self-tapping screw is not visible).

PIR and PUR panels are produced in thickness from 40mm to 200mm, mineral wool is thick from 60mm to 200mm. and with a polystyrene core from 50mm to 250mm.

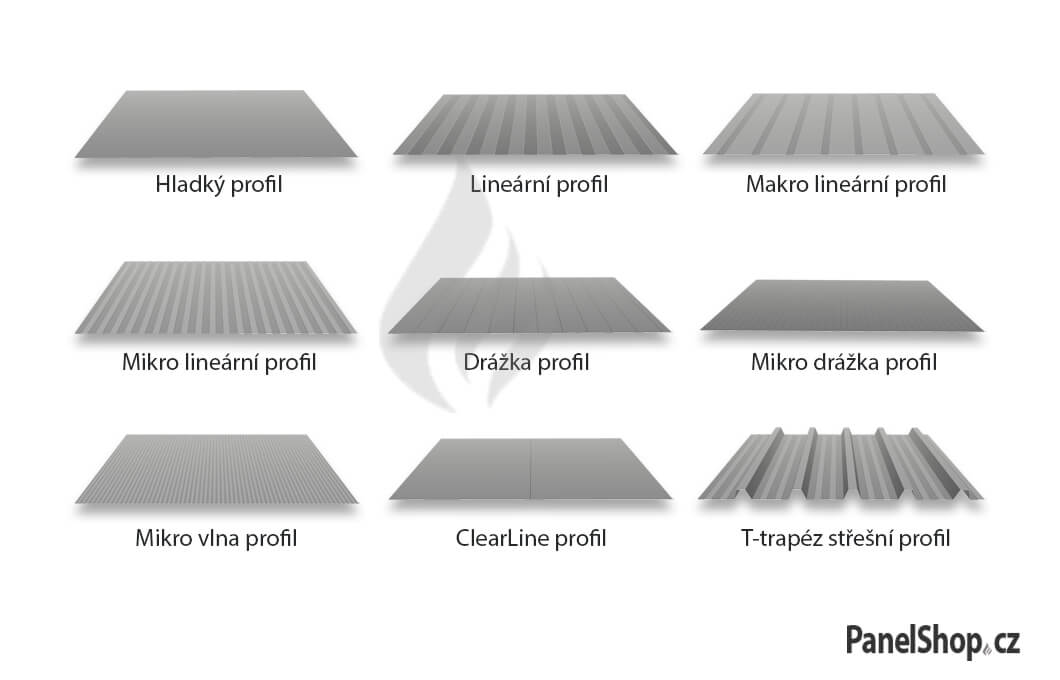

The most used and available plating profiles

A galvanized steel sheet with a thickness from 0.4 mm to 0.7 mm is used on the inside and outside. The standard thickness is 0.5 mm. The most used and most available profiles are: smooth, linear, macro linear, micro linear groove by micro grooves, microwave, ClearLine, t-trapezoid.

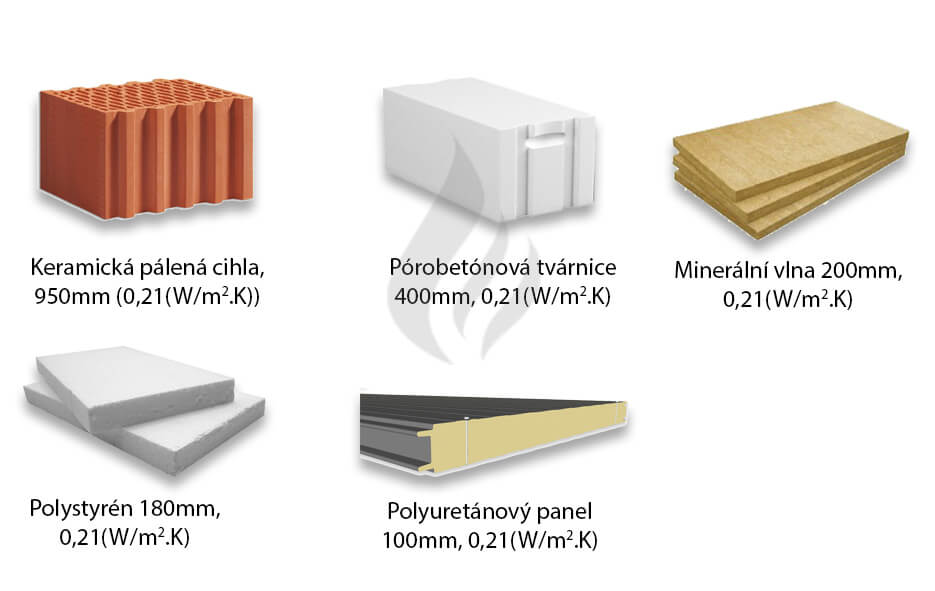

Quality thermal insulation ability

The core is usually mineral wool, polystyrene core (EPS), polyurethane foam (PUR), as well as their improved version, highly resistant to fire – polyisocyanurate (PIR). These materials are considered the best and most used in the field of insulation, and therefore their thermal insulation ability is one of the dominant advantages of sandwich panels.

Thermal insulation capacity (U [W / m2K])

- PUR / PIR panels – from 0.59 (W / m2.K) to 0.14 (W / m2.K)

- Panels with mineral wool – from 0.66 (W / m2.K) to 0.19 (W / m2.K)

- Panels with a polystyrene core – from 0.73 (W / m2.K) to 0.19 (W / m2.K)

For a better comparison

Light weight and easy transport

The panel weights range from 9.9kg/m2 (40mm, PUR panel) to 37.5kg/m2 (200mm, mineral wool panel), which represents a low weight and very good conditions for transportation, unloading and assembly itself.

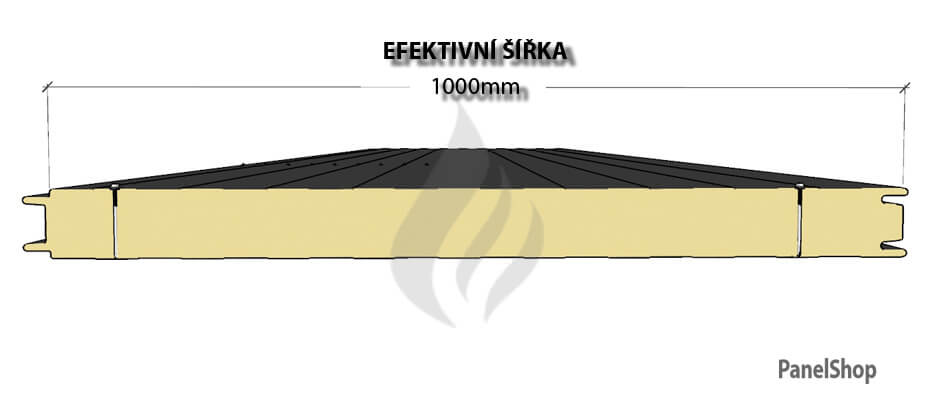

What is effective width…

Effective panel width means the visible width of the panel without the joint. Widths vary from 1100mm (e.g. (PUR / PIR – wall SP, visible joint), 1050mm (e.g. Mineral wool – facade, hidden joint) to 1190mm (e.g. Polystyrene core – roof, visible joint).

Minimum – maximum length of the panel

The minimum length of the panel is 2m and the maximum length of the panel is 18m. It depends on the selected species. The recommended maximum length is up to 12m, due to transport in trucks. When requiring longer dimensions such as 12m, special transport must be arranged, which of course also increases the cost of the total price. When ordering, specify the number of pieces and the length of the panels according to the project (they are made to measure).

Fire resistance and sound insulation

Fire resistance examines the ability of sandwich panels to withstand a fully developed fire. The classification of integrity (E) and isolation (I) in minutes is most often given. Mineral wool (EI120) has the best fire-resistant properties, then polyisocyanurate core (EI30) and polystyrene core (EI15) has the weakest properties.

The term weighted sound insulation (Rw) is a single-number assessment of the reduction of sound transmission through a partition structure or other building element. This single digit value is approximately equal to the average sound reduction in the middle of the sensitivity range of human hearing. In our case, the dividing structure is a sandwich panel, which achieves very good values, for example, the polyurethane panel has Rw = 26dB, mineral wool has Rw = 32dB and the polystyrene core has Rw = 23dB.

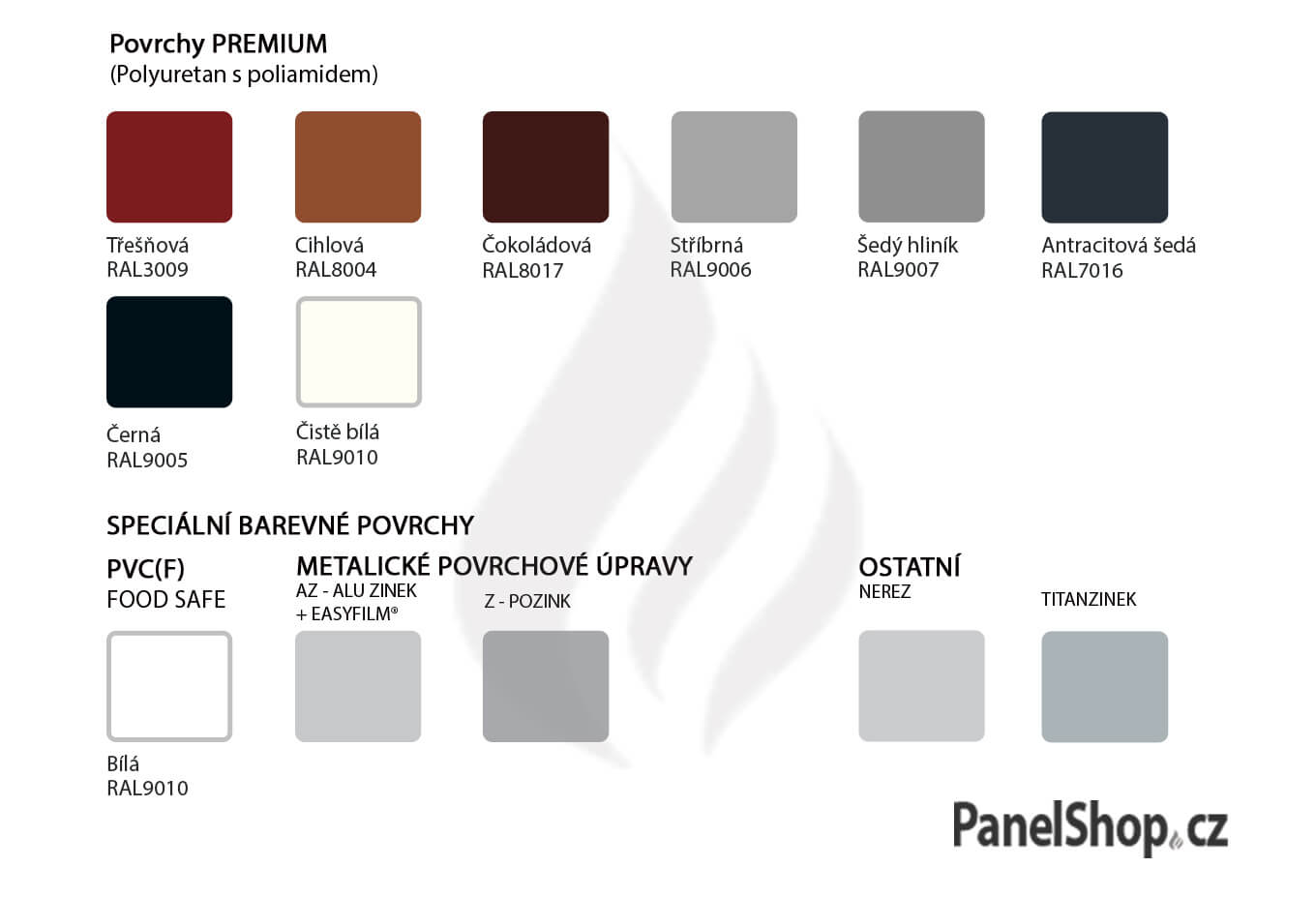

Colors in RAL shades

All offered colors are in RAL shades, as this is the standard used in industry and construction. Color availability must be approved by the sales department prior to placing an order. Possibility of choosing a color according to your individual requirement in RAL color. The standard colored surface is polyester. The option of choosing a premium treatment from polyurethane with polyamide, metallic surfaces from zinc or aluzinc, stainless steel or titanium-zinc.

PREMIUM SURFACES

- Polyurethane surface treatment with 55 μm thick polyamide

- Corrosion resistance up to RC5

- UV resistance RUV4

- High scratch resistance

- Color constancy throughout the life cycle

ZINC

- Thickness of surface treatment 20 μm

- High resistance to corrosive agents and mechanical damage

- Environmentally friendly, chrome-free, meets EU requirements

ALU ZINC + EasyFilm

- Surface treatment thickness 20 μm (150 g/m3) and 25 μm (185 g/m3)

- Resistance to elevated temperatures

- High corrosion resistance

- Environmentally friendly, chrome-free, meets EU requirements

PVC(F) food safe

- Surface treatment thickness 120 μm – white film – special layer with increased hardness – for use in food facilities, refrigerators (easily washable)

ORGANIC SURFACES

- 25 μm thickness surface treatment

- Corrosion resistance up to RC3

- Resistant to temperature changes and atmospheric influences

MATTE PEARL

- Thickness of surface treatment 35 μm

- Corrosion resistance up to RC3

- Resistant to temperature changes and atmospheric influences